In our laboratory at the University of Colorado at Colorado Springs, we built and instrumented a solar-powered fluidyne (liquid piston heat engine) test bed. [1]

The test bed was intended to serve two purposes. First, it was used to demonstrate direct solar-powered operation of a fluidyne with sunlight concentrated directly on the fluidyne cylinder rather than on a remote heat exchanger. In addition, it was used to characterize some aspects of the operational thermodynamic cycle. The test bed was only intended as a platform to explore feasibility and thermodynamic characteristics, not as a practical, power producing engine. The test bed was to be powered by the sun using a 50” by 37” Fresnel lens. The Fresnel lens supplied ample solar power for the fluidyne.

Measurements of temperature and pressure inside the working space of the engine showed that a temperature gradient existed across the working space at all times.

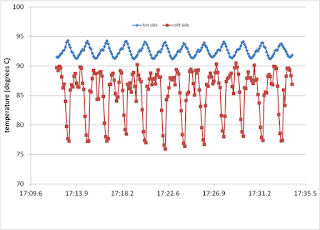

This figure shows about 20 seconds of temperature data from a single test. During this segment, the temperature fluctuations on the hot side were about 4 °C, and the temperature fluctuations on the cold side were approximately 12 °C. As expected, the temperature fluctuations from the two thermocouples are out of phase with one another.

This figure shows a pressure-volume plot of the working space. The enclosed area represents the work of each cycle. This engine was operated without any external load for this phase of testing. Therefore, the indicated cycle work is only overcoming internal friction and other losses.

The instrumented solar-powered fluidyne test bed demonstrated consistent and repeatable operation. The Fresnel lens used provided ample energy to power the fluidyne. Indicated work of the engine was collected with pressure and volume measurements. Since the engine was unloaded, this work only overcame frictional losses.

[1] J.W. Mason and J.W. Stevens, 2011, “Design and Construction of a of a Solar-powered Fluidyne Test Bed” Proceedings of the ASME 2011 Mechanical Engineering Conference and Exposition IMECE2011, November 11-17, 2011, Denver, Colorado, USA, paper IMECE2011-62194.

Hi, James, I started "pallet gardens" in August and they are watered with airlift pumps that are powered by a 2 psi 60 litre per hour aquarium bubble pumps 3.5 watt. Could a fluidyne Stirling make 60 litres per hour of 1 psi air? Airlift pumps in 1/4 inch tubing or 3/16 tubing is remarkable. I can pump to over 6 ft high using under 4 inches of submergence! 20 to 1 lift to submergence ratio! Anyway a low performance liquid piston pump would do the job it it manage 1 psi and 60 litres per hour of air! Check my youtube for more details http://www.youtube.com/watch?v=xK9TfgxTHDo

ReplyDeleteInteresting approach! I'm sure a fluidyne could be constructed to meet that flow rate, but surely not as compactly as a simple bubble pump.

ReplyDeleteThanks James. I just want to investigate that option for poor areas with no electricity. I keep looking and it should be quite simple. There will be no real sun here for another month or so so it is time to research this material.

ReplyDeleteBrian